Despite the risks associated with pollution in ventilation and air-conditioning systems, there are no regulations forcing companies and properties' managers to have the systems regularly cleaned. A defined responsibility to manage ventilation systems' hygiene only applies to medical care establishments – cleaning has to be performed there every 2 years. On the other hand, Minister of Work and Social Policy Regulation from 1999 relating to general OHS regulations clearly states that ventilation and air-conditioning installations must be maintained properly. The employer is responsible for providing a healthy work environment for the employees. Neglecting the system's hygiene may cost the employer around 1-2 thousand Zloty in fines, and in some cases a petition may be filed in a court, which in turn may mean a fine of 30 thousand Zloty.

Although cleaning the system and the filters or changing the filters is a rather burdensome duty, the lessees and the managers should be persuaded by the fact that only well-maintained installations can the parameters proposed by the designer be achieved. In other words, a polluted ventilation will not be effective – it will not provide the required amount of fresh air to individual rooms. In addition, germs, bacteria and viruses that are not stopped by the filters will move freely through the installation, causing more occurrences of sickness among the employees and a significantly lower work efficiency.

A virus in the ventilation shaft

A serious ecological and logistic issue resulting from neglecting the ventilation and air-conditioning system can be the significant increase in sickness among employees mentioned before. An extreme example is legionellosis, causing pneumonia and even death in some rarer cases. Legionellosis bacterial infection has symptoms similar to those of angina. The risk of sickness is increased in case of staying in big groups of people, like public institutions, especially in warm and damp places.

People working in air-conditioned rooms much more frequently suffer from upper respiratory tract diseases, accompanied by a very sore throat, fever and a running nose. In irregularly cleaned installations viruses and bacteria can spread, which are then transported to individual rooms in the property.

Changing the filter

In case of ventilation and air-conditioning systems, the filter is the element that becomes damaged the most often. The frequency of changing the filter depends on the conditions outside the building – explains Ireneusz Makowski, owner of CLIMA-BUD company. It may be that the filter needs to be changed every 2 weeks, but on average it's every 3 months, with a minimum of one change a year. If the filters are equipped with electronic information systems on the pollution status (nowadays it's usually the standard), which can be accessed from the electric switchboard that operates the ventilation system, then the change takes place after the automatic switchboard has switched on an alarm. Other symptoms include stuffiness, condensation on the windows and an unpleasant smell coming from the ventilation system.

It is worth remembering that a polluted, blocked filter will significantly decrease the ventilation system's efficiency. The system lets through less and less air which means that the central unit must work much harder to ensure that the requirements of individual rooms are fulfilled. Changing the filter too rarely causes the pollution to spread throughout the whole system of wires in the ventilation system as well as higher exploitation costs and a bigger energy usage – warns Ireneusz Makowski.

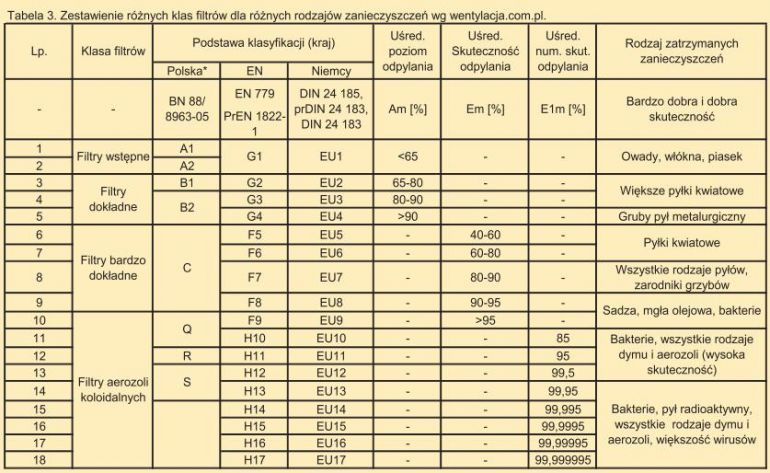

Filtering the air

Why is it important to ensure the cleanliness of filters and the whole system? Before the air comes from the outside into the individual ventilated or air-conditioned rooms, it must be filtered due to its decreasing quality (filters also extend the ventilation and air-conditioning systems' life). On the surface of the filter pollution gathers, particulate matter from the air. Some materials absorb and stop gases and small dust (like allergenic pollen).

Non-woven filters are most commonly used, whose durability and efficiency depends mostly on the type of material they were made from. They may be polyester, glass, polyurethane or latex fibres. For example, glass fibres are resistant to high temperatures (up to around 300 degrees Celsius) and acids, and they do not absorb water.

Activated carbon filters are used much more rarely, which, however, stop and absorb gases from the air very efficiently. Installation of this type of filters should take place especially in blow-in ventilators on the side that pumps the air in, as they eliminate all unpleasant odours (for example car fumes). Apart from that the filter filler becomes a soundproofing layer.

If we require the most efficient filter, we need to choose a product with a really dense structure, which will absorb pollution of the smallest diameter. However, it is worth remembering that it may increase the air resistance in the installation. Sometimes it may be impossible to achieve an ideal filtration level together with high parameters of the ventilation system's performance.

In addition, if we want to maintain the ventilation or air-conditioning system as hygienic as possible, we must include certain aspects already in the design stages. Enabling inspection and cleaning is particularly important, in other words, providing an easy access to the installation.