In spite of the fact that a low-energy construction was a certain curiosity ten years ago, now it does not surprise anyone. The usage of energy-saving materials and implementation of solutions which provide decrease of the loss of heat remain the base of almost each building project, no matter if it concerns a dwelling house or office structure.

Air cells

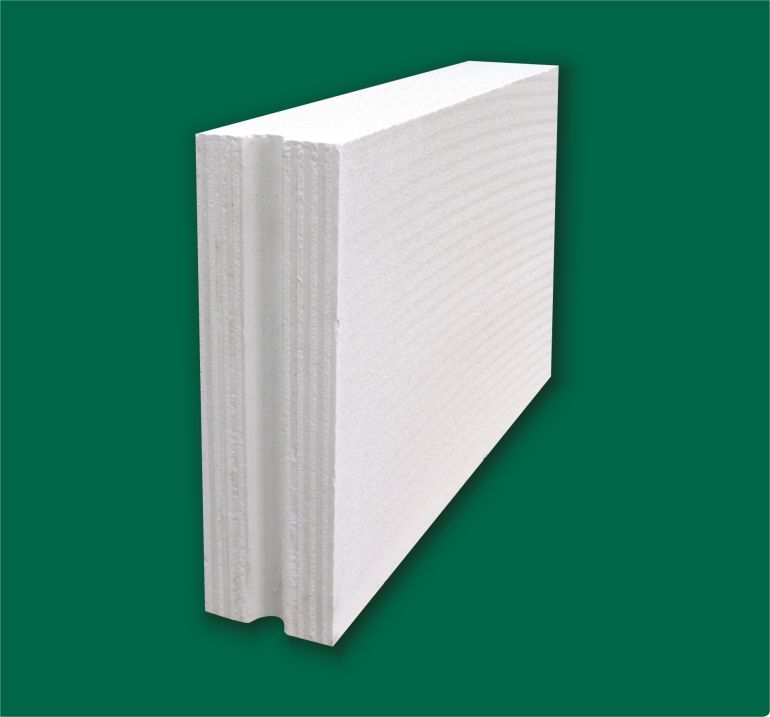

The choice of materials in order to built a structure will decide on its future exploitation. The key issue here is the ability to hinder uncontrolled exchange of heat with environment, which will have an influence on heating and cooling costs. Therefore, the office should be composed of materials with the best, that is the lowest, heat permeability parameter, such as cellular concrete, which performs two functions at the same time: constructive and insulating. Cellular concrete is one of the most energy-saving wall materials – points out Robert Janiak, advisor for investments and projects in H+H Poland. Mainly, the internal structure of a material which is composed of great quantity of pores, in which the best heat isolator – that is air – is trapped, has an influence on it. Thanks to it, walls made from pads of cellular concrete reach the lowest values of U heat interfusion rate. The material does not have competition in this category. Unique structure of cellular concrete is related to the usage of hourogenic means in the form of powder or aluminum paste. Thanks to it, concrete mass is foamed and gas bubbles are created, that is characteristic cells filled in air.

The energy efficiency of cellular concrete is also related to an ecological productive process – low consumption of energy and resources needed to its production. Construction material, which is being produced in low densities like 350, 400 or 500 kg/m3 , requires smaller amount of resources and energy than its competitors with greater density and weight – continues Robert Janiak.

Good parameters

Physical properties are directly related to structure and density of a material – the same in each point of a built wall. It has an impact on uniformity of partitions and minimization of risk of arising thermal bridges through which the heat may escape. However, an energy-saving material is a half of success. The quality of conducted works and application of proper and thinly-joint glue mortar are equally important. We cannot also forget about other properties of concrete which enable easier performance of works. The easiness of installation follow from a porous structure of cellular concrete which has an influence on lightness of cellular concrete elements and easy as well as quick processing of a material – truncation, cutting and drilling – explains expert in H+H Poland. The easy processing does not mean the lack of concrete’s ultimate strength which is characterized by high resistance to squeezing at proper density. Of course, the better density, the better parameters of a material. However, concrete with low density is also used in realization of multi-storey structures, especially in case of outside and complementary walls. Their resistance to squeezing is not so crucial. Besides, cellular concrete with low density is characterized by better heat parameters.

The material may be widely applied: producers offer not only resistant elements of ceilings, flat roofs and lintels, but also pads, tiles and wall panels. Special wall panels are particularly recommended because we want to conduct works as quick as possible and we would like to have freedom in creating space of the office.

When cellular concrete?

However, does cellular concrete meet all requirements of specialist office construction, including these energy-saving and passive? By all means, although we should remember about certain fields of application. Generally, the office construction sector is difficult for all brick walls – says Robert Janiak in H+H Poland. Dominant construction materials in this sector are reinforced concrete (main supporting construction), system glass coverings, stone and plastic (buildings’ elevations) and gypseous and cardboard walls (internal partition walls). However, cellular concrete is also applied in office buildings, for instance, in inner walls as technical and sanitary walls of rooms, on jackets in installations shafts or in inner walls as those which fill a reinforced concrete structures. Cellular concrete is prized in such applications on account of two advantages: mentioned easiness of installation and perfect fire resistance. The perfect fire resistance of cellular concrete is owed to thin partition walls which are 115 mm wide and have 2-hour fire resistance (EI1 20) and walls which are at least 175 mm wide reach maximal fire resistance class, that is 4-hour REI240 – he points out.

In case of enormous investments, like office building, time of realization and quality as well as resistance of used components are extremely important issues. Cellular concrete may turn out to be an attractive alternative for other materials.